- #PROCESS FLOW DIAGRAM TOOLS HOW TO#

- #PROCESS FLOW DIAGRAM TOOLS SOFTWARE#

- #PROCESS FLOW DIAGRAM TOOLS ISO#

Development of new integration methods and model flow diagrams.

#PROCESS FLOW DIAGRAM TOOLS ISO#

PFDs of many commercial processes can be found in the literature, specifically in encyclopedias of chemical technology, although some might be outdated. Often PFDs are produced on large sheets of paper. Rules and symbols are available from standardization organizations such as DIN, ISO or ANSI.

#PROCESS FLOW DIAGRAM TOOLS SOFTWARE#

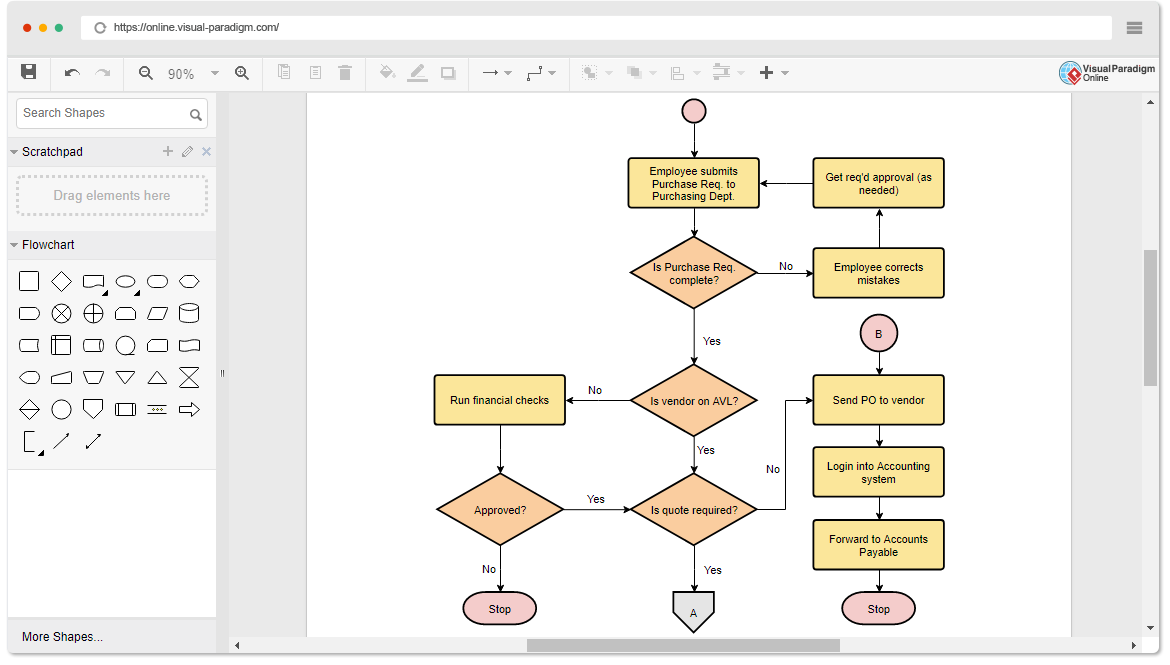

The process flow diagram below depicts a single chemical engineering unit process known as an amine treating plant:Ī typical oil refinery-SL Other items of interest Ī PFD can be computer generated from process simulators (see List of Chemical Process Simulators), CAD packages, or flow chart software using a library of chemical engineering symbols. Process flow diagrams of multiple process units within a large industrial plant will usually contain less detail and may be called block flow diagrams or schematic flow diagrams. Controllers like Level Control or Flow Control.Process flow diagrams generally do not include: Operational data ( temperature, pressure, mass flow rate, density, etc.), often by stream references to a mass balance.Major bypass and recirculation (recycle) streams.Typically, process flow diagrams of a single unit process will include the following: Or, you can click on one of template thumbnails to open a pre-made template.Some typical elements from process flow diagrams, as provided by the open source program, Dia. Select Electrical Engineering > Process Flow Diagram and click the + to enable a blank page.To create a PFD online, open EdrawMax Online( ) on your laptop or PC.Your goal might be to provide quality assurance, documentation, or improvement. ğinally, your diagram is ready to be used for its intended purpose.It is vital to make a draft and seek approval from the people involved in this process because it will help you to make necessary changes, you can add stuff, or delete any errors. Now draw a rough sketch and confirm it with your team members.Furthermore, it is crucial to study the standards of whatever you are trying to produce in the process. If you are making a new process model, try to learn and understand the available data. It is essential to study relationships, activities, and equipment with the help of interviews and observations.Various editions of PFDs are available for intricate processes that you can use or draw to communicate with people. Next, decide what kind of details you will need for your purpose.Mention what you want to study and what you will obtain from it. ğirst, you need to define your process’s scope.To plan and create a PFD, you have to follow these steps mentioned below.

#PROCESS FLOW DIAGRAM TOOLS HOW TO#

How to Plan and Create a Process Flow Diagram

0 kommentar(er)

0 kommentar(er)